Standard Operating Procedures, which are step-by-step instructions, act as guidelines for how to use and maintain your coders for best Print Quality.

Improve Employee Productivity, lower operating costs with clear instructions

Improving Print Quality with Carton to printer Spacing, Cleaning and Maintenance

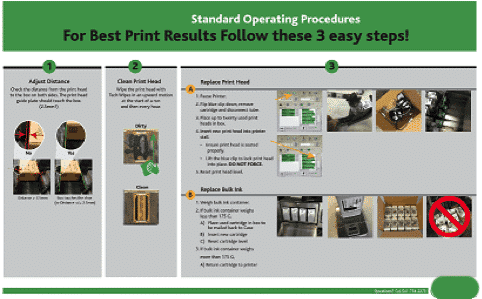

Distance: Upon noticing a sudden degradation of print quality, the first thing to check is the print distance. If the coder is too far from the substrate then the print quality will suffer.

Dust from corrugate, paperboard or the product itself can also contribute to poor print quality. Properly cleaning the printhead can make all the difference.

Clean: For porous surfaces using water-based (non solvent) inks, try a small amount of deionized water and a lint-free cloth to the clean the nozzles of the printhead.

For non-porous surfaces requiring solvent inks, still use the lint free cloth but NO deionized water is necessary. Hold the cloth against the printhead for 5 seconds before wiping (blot).

When all else fails, you may need to replace the cartridge and printhead. Be sure to affix the plastic clip to the cartridge before sending it back to the company where the ink was purchased.

Contact Case Printing Solutions to create Standard Operating Procedure guidelines that are specific to your production environment. We’re also your Go-To resource for affordable inkjet equipment and supplies.